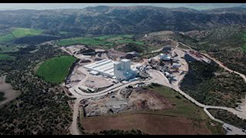

TOMRA Delivers Results for Mothae Diamonds

The Mothae mine, located in the Maluti Mountains of Lesotho is known to produce large, high-value diamonds which command the second highest dollar per carat for kimberlite diamonds worldwide. The company relies on TOMRA’s XRT sorting technology and digital solutions, the TOMRA Insight platform and TOMRA ACT user interface, to recover large unbroken diamonds from the mine with high sorting efficiency and high throughput, while benefiting from lower operational costs.

The recovery plant operates two TOMRA COM Tertiary XRT 1200 sorters: one for fines from 10mm to 20mm, and the other for coarse materials from 20mm to 45mm. The ore extracted from the mine is treated through primary crushing, scrubbing and screening, then transferred to the recovery area. The two TOMRA XRT sorters at Mothae are connected to the TOMRA Insight cloud-based data platform that turns the machines into connected devices that generate valuable data and puts operators in control of the sorting process. They also feature the TOMRA ACT user interface, which facilitates the optimization of the workflow and improves productivity.

“We wanted to recover large diamonds at the highest sorting efficiency with the highest throughput, and TOMRA met Mothae’s requirements with its modern and innovative technology,” said Macobone Semelane, Recovery Superintendent.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2024-05-08 | TOMRA MINING | Germany | Views 164