Tomra Mining Offers Sensor-Based Ore Sorting

When processing sulfide ores to extract copper, zinc or lead, the focus is on ensuring the mill is always operating at full capacity. One challenge is to optimize the process by eliminating waste in the early stages and maintain a high recovery rate. The technology to sort copper, zinc and lead sulfides is available from TOMRA Mining. The company say their X-Ray Transmission (XRT) sensor-based sorting technology can effectively detect sulfides in mineralized run of mine material, as they carry elements with higher atomic densities than non-mineralized waste rocks.

TOMRA’s XRT sorters scan the individual rocks fed into the machine on a conveyor belt with overhead X-Ray sources. At the same time, detectors located inside the belt collect data from the ore. The position of sensors, close to the rocks, combined with the strong X-Ray power sources result in extra high-resolution images. This can enable TOMRA’s XRT sorters to process even the most challenging porphyry copper disseminated deposits. Waste rocks are ejected by high-precision, fast pneumatic module, which adds to the sorter’s efficiency, says Tomra.

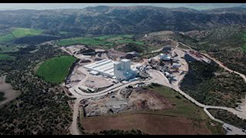

“A bulk test was conducted to evaluate TOMRA's XRT technology, and subsequently, the company decided to test it continuously in a pilot installation at the Antas Norte site. The results were consistent in both tests, demonstrating that the technology is effective for industrial application. TOMRA’s technology holds significant potential for OZ Minerals Brazil’s strategic plan, with the possibility of making deposits with lower ore grades viable, reducing operational costs, enhancing transportation safety for pre-concentrated ore, as well as decreasing the CO2 emission resulting from this activity.”, said Heitor Mesquita Carmelo, Plant Manager at OZ Minerals Brazil.

For more information

Categories: Mineral - Processing Equipment Mineral - Processing Services

2023-09-29 | TOMRA MINING | Germany | Views 467