Sandvik Introduces New Push Bore Reamer System

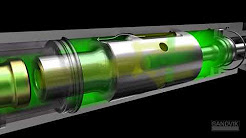

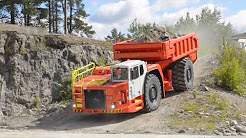

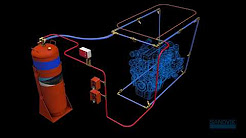

Sandvik is introducing a new push bore reamer system that it says will improve penetration rate, minimize downtime and simplify in-field service in underground slot hole drilling.

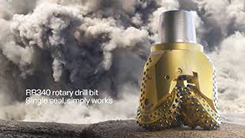

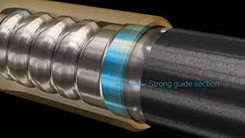

The tool system includes two Ø740-millimeter push bore reamers, one for upwards and one for downwards push boring and a fit-for-purpose cutter. Key upgrades include simplified in-field service with bolted-on wing and wear pads and a patented saddle design for better material clearing in the cutter pocket. The cutter itself is equipped with a tougher carbide grade and a steeper cone angle on the shell to reduce skidding and carbide damage. It also features an improved bearing design and more heat-tolerant grease.

“Our customers will experience fewer cutter changes, easier in-field spare part replacements and reduced service-related transportation, improving both safety and sustainability. We also took the opportunity to design both up and down Ø740 reamers to utilize identical spare part components as far as practically possible, and this sufficiently reduces inventory demands when you plan to drill with both reamers.” said Russell Clayton, Product Manager Raise Boring at Sandvik Mining and Rock Solutions.

For more information

Categories: Drilling - Equipment and Supplies

2024-02-02 | Sandvik Mining and Rock Solutions | Sweden | Views 333