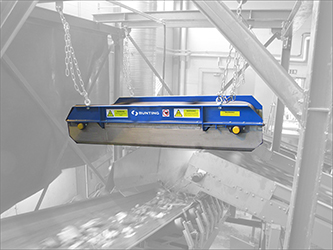

Bunting Electro Magnet Improves Quarry Productivity

Atherton Material Handling recently installed a Bunting Suspension Electro Magnet at a calcium carbonate quarry in Melton, UK, aiming to enhance efficiency by reducing frequent metal detector trips. Designed to remove tramp ferrous metal from the conveyed material before reaching the metal detector, the Bunting Suspension Magnet can reduce the need for stoppages, improve productivity across the quarry’s operations.

The installation follows a request from Atherton Material Handling, whose team sought a solution to frequent trips from the existing TN77 series metal detector. The detector, which Bunting had previously supplied, was effectively identifying tramp metal, thus preventing equipment damage. However, the frequent presence of ferrous contaminants led to productivity challenges. The new Suspension Magnet now removes ferrous metal before it reaches the detector, allowing the detector to focus on non-ferrous metal while minimizing conveyor stoppages.

“We worked closely with the Atherton Material Handling team to find a solution for their client. The final solution not only maintains and improves important protection against tramp metal damage, but also makes it easy and safe to operate and clean the Suspension Electro Magnet.” said Tom Higginbottom, Bunting’s Technical Sales Engineer.

For more information

Categories: Magnets

2024-10-31 | Bunting - Redditch | United Kingdom | Views 36