Tenova - New Electric Arc Furnace for Valbruna ASW Inc

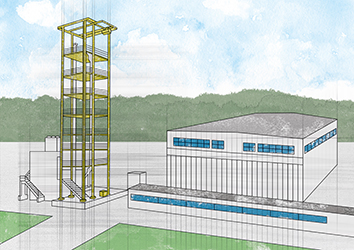

As part of it’s green transition of the metals industry, Tenova recently completed the successful start-up of the new 70t EAF at the Valbruna ASW Inc. plant, located in Welland, Ontario (Canada). Valbruna ASW is a premier specialty steel producer that manufacturers high quality steel and stainless steel.

Tenova’s latest generation EAF unit has replaced an older EAF vessel. The spout shape of the new furnace will provide an increase in melt shop productivity as well as an improvement to the production reliability of manufacturing specific high-quality steel and stainless steel grades.

The scope of supply also included associated auxiliary equipment, the innovative TDRH 4.0 (Tenova Digital Regulator and Harmonics) electrode regulation system, the KT (Koester Technologies) chemical injection system, a ladle-charging material handling system and complete EAF automation. The KT chemical injection system is designed to fit the wide range of process needs, balancing the energy distribution and increasing the efficiency and productivity. The new automation system provides several advantages which will increase the efficiency of the plant. The system will guarantee the correct execution of the working cycle in relation to the production of different steel grades, while optimizing the parameters and storage of production data. The system is also designed to comply with all safety standards.

“We are proud of the innovative and state-of-the-art EAF design achieved for Valbruna ASW. It is through our important and long-term relationship with the Valbruna Group that this project was made possible. We have increased the plant’s production, sustainability and safety. We expect the plant to become a landmark for the production of high quality steel and stainless steel in the North American market”, said Aldo Savioli, Project Manager Operations at Tenova Upstream.

For more information

Categories: Furnaces

2023-02-20 | Tenova | Italy | Views 530